In the context of the rapid evolution of modern electronic devices towards "lightweight and compact" and "high-density integration", traditional welding processes have become increasingly inadequate. Especially in the fields of precision manufacturing such as chip packaging and microsensors, the requirements for solder joint accuracy, reliability, and thermal control have reached unprecedented heights. It is precisely in this industry bottleneck that blue light laser solder ball welding technology has emerged, with its revolutionary advantages, becoming the core driving force for upgrading high-end electronic manufacturing.

Technical principle: Integration of light and precision

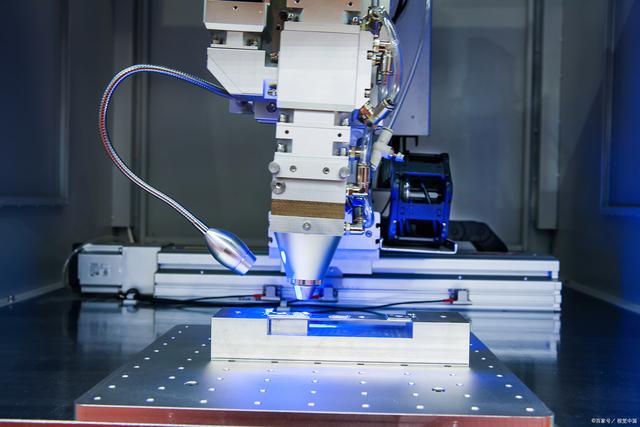

Blue light laser solder ball welding is an advanced non-contact welding process. Its core lies in using a blue light laser with a wavelength of about 450 nanometers as the energy source. Compared with traditional infrared lasers, blue light has a very high absorption rate for commonly used metals in the electronics industry such as copper and gold, which brings fundamental changes.

The process is carried out in a closed nitrogen environment and can be divided into three steps: first, a single tin ball is fed into a specially designed nozzle; Subsequently, the blue light laser instantly melts the tin ball and precisely sprays it onto the target solder pad under nitrogen pressure; Finally, the metallurgical bonding with the solder pad is achieved by utilizing the heat generated by the solder ball itself and the continuous laser energy. The entire process does not require soldering flux, avoiding chemical residues and achieving truly clean soldering.

Core advantage: Triple leap in efficiency, accuracy, and reliability

The introduction of blue light laser has brought a qualitative improvement to solder ball welding, and its advantages are mainly reflected in the following aspects:

Doubling efficiency and significant energy savings: Research has shown that the efficiency of blue light laser welding can be significantly improved compared to infrared laser welding. When achieving the same welding effect, the required energy is significantly reduced, effectively saving energy consumption and operating costs.

Minimal thermal impact, protecting precision components: Due to high energy absorption efficiency, welding requires less heat input and has a shorter operating time. This results in the heat affected zone being controlled within a very small range, effectively avoiding damage to surrounding thermal sensitive components and flexible substrates from high temperatures, making it particularly suitable for soldering products such as camera modules and FPC (flexible circuit boards).

Precision reaches micrometer level: This technology, combined with a high-resolution visual positioning system, can achieve extremely high soldering accuracy, meeting the requirements of semiconductor level packaging.

Consistent quality and environmental friendliness: The independent supply of single balls ensures the uniformity of material used for each solder joint, resulting in a full and consistent molding of the solder joints. The "dry" process of using solder throughout the entire process eliminates pollutant emissions and subsequent cleaning steps, which is in line with the trend of green manufacturing.

Application and Prospect: Empowering the High end Manufacturing Industry Chain

With the above advantages, blue light laser solder ball welding technology is rapidly penetrating into fields that require extremely high precision and reliability.

Semiconductor packaging: Creating micro bumps in wafer level chip packaging is an ideal solution to replace traditional electroplating and solder paste printing methods.

High end consumer electronics: widely used in the welding of mobile phone camera modules, acoustic devices, micro connectors and other components, it is a key process supporting the miniaturization of consumer electronics products.

Medical and automotive electronics: In medical devices, the characteristics of low thermal damage and high reliability are crucial. At the same time, it can also meet the strict automotive grade requirements for solder joint strength and reliability in new energy vehicle battery management systems, IGBT modules, and other applications.

Looking ahead to the future, with the booming development of 5G, artificial intelligence, the Internet of Things, and the new energy vehicle industry, the integration of electronic components will inevitably reach a new level. Blue light laser solder ball welding technology, as an advanced manufacturing method with high precision, high efficiency, and low damage, will continue to expand its market demand. It not only solves the pain points of current precision welding, but also provides a solid and core process foundation for the innovative design and reliable manufacturing of the next generation of electronic products.